The structural composition of high temperature resistant labels includes surface material, adhesive, and backing paper. 1. High temperature resistant label surface material: 25um (or 50um) coating treated polyimide film. The uncoated polyimide cannot meet the performance requirements, while the coating treatment can better meet the printing barcode properties required by the process and the requirements for material color and glossiness. 2. High temperature resistant label adhesive: Currently, adhesives are generally divided into three categories: rubber, acrylic, and silicone

Ordinary self-adhesive label paper can withstand temperatures ranging from 50 ℃ to 80 ℃, but in special industries such as electronics and new energy, or in high temperature environments above 100 ℃, ordinary self-adhesive label paper may experience delamination, glue melting, and other issues. This requires the use of high-temperature resistant adhesive label paper.

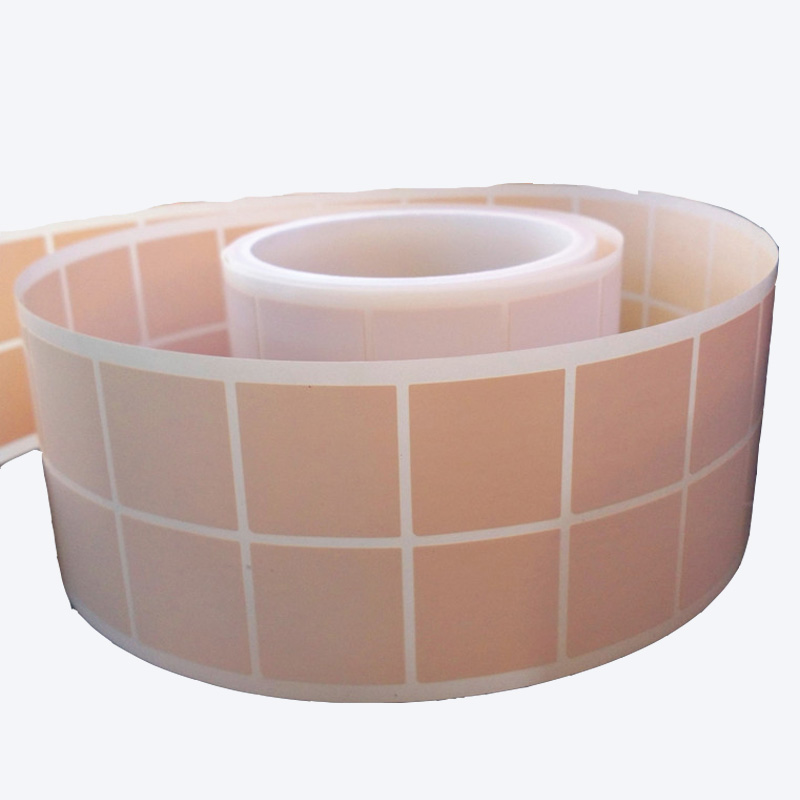

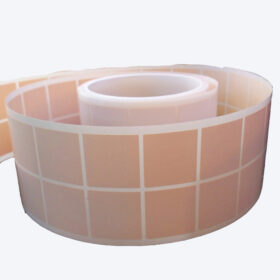

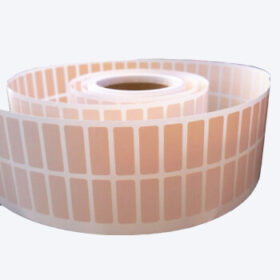

High temperature resistant self-adhesive stickers are label papers made of high-temperature resistant materials. Firstly, high-temperature resistant label surface materials such as PET, polyimide film, etc. are selected, and they can also withstand temperatures above 100 ℃. Under high temperature conditions, their performance is stable: strong adhesion, unchanged color, unchanged yellow when exposed to high temperature, labels do not fall off or curl up, do not peel off, and the glue does not melt.

ฉลากผลิตภัณฑ์

ฉลากผลิตภัณฑ์